Product Description

High Pressure Safety Filter

Structure

Multilayer outer net with folded wires + inner support frame

Function

Final safety filtration before spunlace jet head.

Advantages

High filtration precision, large filtration area, high pollutant retain, high flow, high temperature and high pressure resistant, can be cleaned and reused repeatedly

Filter Cartridge for Spunlace Machine

Structure

Five layers composite sintering net. (when at high pressure an outside support frame can be added)

Advantages

Filtering gap uniform, with accuracy and stability, easy to backwash, the screen strong and solid, high temperature and high pressure resistant.

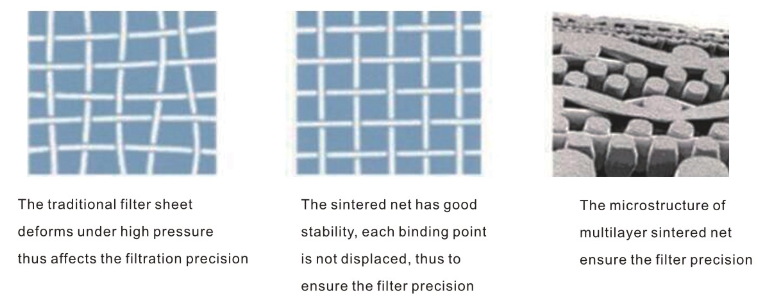

Safety Filter

Our police filter has multi-layer net cartridges with sintering process,inside there is support frame. The filter uses folding technology to increase filtration area, the use of sintering technology is to ensure binding points under high pressure, no deformation to occur, this has increased the filter lifetime. It has provided high-quality products for many domestic spunlace producers. Sintering process applied, no distortion, achieves excellent filter effects. It is corrosion-resistant,easy to clean and easy for removal.

Filter Cartridge

We supply filter cartridge for the spunlace machine. The tailor made sintered filter fits well the spunlace sizes, with good accuracy and stability, and strong pollutant carrying capacity, can be cleaned repeatedly, and no distortion.

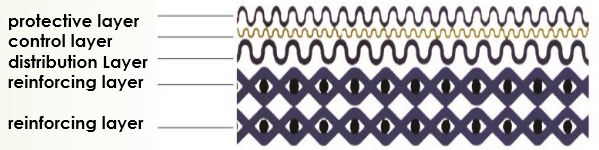

Structure

We supply various kind of sintered metal net, the multi-layer sintered mesh is of stainless steel net or sintered metal fiber felt (ranging from 2-50 layers). The 5-layer sintered net for example, is a normal type, it has 2 reinforcing layers, a distribution layer, a control layer, and a protective layer, stacking together and sintered at high temperature, then pressurized, is widely used in high temperature under high pressure and corrosion conditions, such as a polymer melt, sewage,chemicals and other filters.

In addition to the normal round and square sintered net, we can also process at customer demand or sample to design and process special sintered net, which max. size is up 650 mm x 1200 mm, with filtration precision at 0.5μm – 200μm.

The most typical and widely used filter cartridge type is from 5μm – 40μm precision sintered net in a cylindrical shape.

Information or Purchase

To get more information about our product or to order from our product, contact us: order@ortekstil.com